The global food industry, long characterized by just-in-time supply chains and centralized sourcing models, is now under pressure. Climate volatility, trade disruptions, pandemics, and regional conflicts have shaken its foundation. In response, companies are diversifying their supplier base to minimize over-dependence on any one source or geography.

While diversification can mitigate specific risks, if not managed strategically, it may increase operational complexity, regulatory exposure, and cost inefficiencies, especially in the delicate world of food supply where food safety is non-negotiable.

This article proposes a cohesive, food-sector-specific framework for managing the risks of supplier diversification, offering guidance for supplier approval and performance evaluation processes.

Understanding Why Diversification Has Become a Food Industry Imperative

The sector operates on tight margins, sensitive timelines, and non-negotiable quality and safety standards. This makes it especially vulnerable to the ripple effects of global disruptions. The key drivers of supplier diversification can be attributed to:

→ Ingredient unavailability

→ Geopolitical instability

→ Trade policy volatility

→ Consumer expectations

Whether it’s a delay in the delivery of critical raw materials or the sudden shutdown of a key supplier due to regulatory non-compliance or contamination, any break in the supply chain can rapidly escalate into product shortages, reputational damage, and lost consumer trust.

A diversified supplier network mitigates these risks by offering alternative sources that can step in quickly when one node of the supply chain falters. But diversification in the food industry is not just about having multiple vendors. It requires a balance between local and international suppliers, vertically integrated partnerships, and rigorous vetting for food safety practices.

Brands that can’t meet those expectations due to upstream vulnerabilities risk not only operational setbacks but also long-term damage to brand equity. Diversification offers an answer, but not without consequences. Therefore, the question is no longer if to diversify—but how to do so safely and sustainably.

Establishing a Supplier Diversification Strategy for Your Food Supply Chain

Implementing an effective supplier diversification strategy in the food industry is more than just expanding your vendor list. While each food business will have unique sourcing needs, a strategic approach guided by planning, data, and continuous evaluation can make all the difference. Here's how to get started:

1. Map Your Existing Supply Chain Risks

Begin by assessing your current supply chain setup. Identify critical dependencies — such as ingredients sourced from a single vendor, products reliant on a particular region, or limited manufacturing partners. These points of dependency represent your highest risk exposure, especially in times of regional instability or supplier failure.

2. Explore & Vet Alternative Suppliers

Once vulnerabilities are clear, proactively search for alternative suppliers. Focus on diversifying across geography, product category, and operational capacity. For the food industry, this also means ensuring that any new suppliers meet relevant food safety standards, certifications, and compliance requirements. It’s not just about having backups — it’s about finding reliable partners who align with your product specifications and delivery timelines.

3. Assess Supplier Capability & Reliability

Don’t compromise on reliability when diversifying. Perform thorough due diligence to evaluate each potential supplier's operational strength, food safety record, audit history, financial health, and capacity to scale. Supplier scorecards, performance metrics, and audit data play a vital role in making informed decisions.

4. Build Strong Supplier Relationships

Managing multiple suppliers requires more effort — but it’s worth it. Establishing strong, transparent relationships is key to successful collaboration. Conduct regular business reviews, maintain open communication, and negotiate clear terms. In the food industry, consistency and traceability are essential — so ensure your partners are aligned on those fronts from day one.

5. Leverage Technology for Better Visibility

With a diversified supplier base, visibility is crucial. Invest in digital supply chain tools like purchase order management systems, supplier performance dashboards, and shipment tracking platforms. These tools offer real-time insights into order status, supplier reliability, and potential disruptions — helping you stay ahead of issues and adapt quickly.

6. Continuously Monitor & Refine

Supplier diversification is not a one-time project — it’s an ongoing strategy. Regularly review performance data, track emerging risks (like regulatory changes or geopolitical events), and be prepared to pivot. Staying informed with real-time supply chain analytics enables food businesses to respond faster to challenges and maintain business continuity.

By following these steps, food businesses can build a strengthened supply chain — one that minimizes risks, meets quality standards, and supports long-term growth in a volatile market.

Why Supplier Vetting Is Essential for a Successful Supplier Diversification Strategy

While diversifying your supplier base is a powerful step toward building supply chain resilience, it also opens the door to new risks — especially if supplier selection is rushed or based on incomplete information. Without a structured vetting process, introducing new vendors can replicate the very vulnerabilities that diversification is meant to address.

That’s where supplier or vendor vetting becomes a critical component. It’s not enough to simply expand your list of suppliers — you need to ensure that each one has been thoroughly evaluated for performance, food safety compliance, operational capacity, financial health, and overall risk exposure. This approach enables food businesses to make informed choices based on the potential impact of supplier failure rather than just cost or convenience.

Choosing pre-vetted suppliers allows your brand to:

- Reduce onboarding time by skipping initial due diligence stages

- Minimize operational risks associated with poor-quality products, late deliveries, or compliance failures

- Gain transparency into supplier capabilities and limitations before entering into a contract

- Streamline audits and certifications by working with suppliers who already meet your regulatory requirements

Risk-based vetting transforms supplier diversification ascertains that every new supplier strengthens your value chain. This is especially important in the food industry, where one unreliable vendor can lead to costly recalls, damaged reputation, or regulatory action. In today’s volatile global landscape, supplier diversification done right, with risk-based vetting at its core, is the difference between merely surviving disruptions and leveraging them as opportunities to grow stronger.

Smart Supplier Simplifies Diversification with Powerful, Risk-Based Supplier Vetting

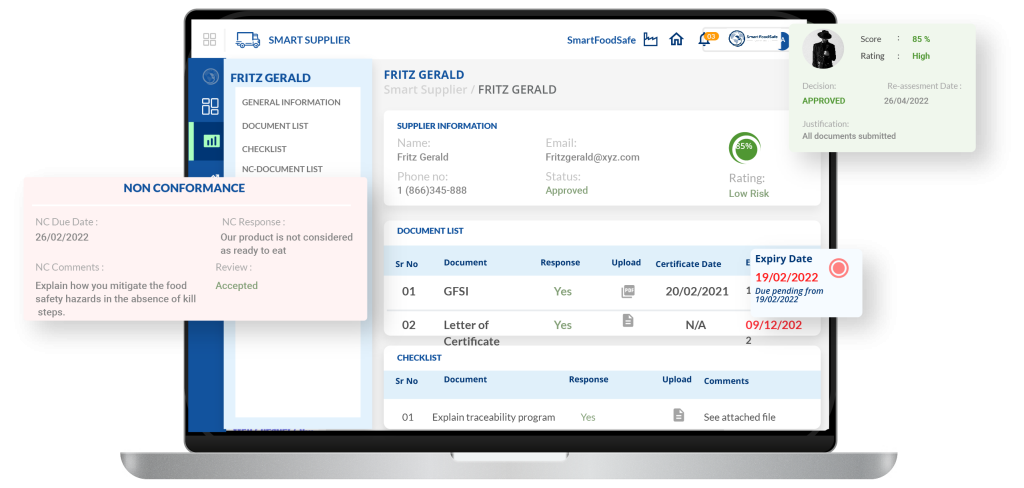

Smart Supplier brings to the table a software solution designed for the evolving supplier base to digitally manage their approval, onboarding, and ongoing performance evaluation. We strive to facilitate this process by:

Make Every New Supplier a Strategic Fit – Smart Supplier enables a structured, impact-driven evaluation of each supplier before onboarding. With customizable qualification criteria, scoring models, and real-time screening, you can ensure that every vendor in your network meets your operational, quality, and compliance standards—right from the start.

Centralized and Automated Supplier Management – Scaling your supplier network shouldn’t mean scaling complexity. Smart Supplier centralizes the entire lifecycle, from onboarding to reassessment, into one intuitive platform. Automated workflows, digital approvals, and performance checklists make the process faster, more transparent, and easier to govern.

Stay Ahead of Disruptions with Real-Time Supplier Visibility – As your supplier base diversifies, Smart Supplier keeps you in control. The platform continuously tracks supplier performance and compliance, triggering reassessments and alerts when risks emerge, helping you respond swiftly—before minor issues turn into major setbacks.

Strengthen Supplier Compliance and Audit Readiness – Smart Supplier streamlines supplier document management, from certificates to audit records, ensuring traceability and easy access. With built-in tools for monitoring non-compliance and audit preparation, your diversified supply base stays aligned with internal and regulatory expectations.

Transform Supplier Data Into Strategic Insight – Smart Supplier’s analytics and dashboards offer a holistic perspective into supplier performance, risk profiles, and approval status. You can compare and rank suppliers, spot improvement areas, and make informed decisions to continuously refine your diversification strategy.