The era of relying on informal agreements to finalize business deals is a thing of the past. In the contemporary business landscape, failing to establish legally binding agreements can expose organizations to significant financial and reputational risks, often resulting in costly lawsuits or unexpected losses. Many consumers may not realize the journey their purchased food products undertake before reaching their hands—passing through numerous stages and involving various entities.

This is particularly pivotal when one think about the fact that delivering a single product often requires uninterrupted collaboration between multiple producers, logistics providers, and service partners. To ensure each step of this process is safe and intact as per the set requirements and protocols, businesses need to rely on well-structured food supply chain contracts. These agreements are key in coordinating interactions across the supply chain, facilitating smooth operations, and safeguarding the interests of all parties involved.

What Are Food Supply Chain Contracts?

Supply chain contracts are formal agreements established between companies and their suppliers, producers, or manufacturers to outline each party’s obligations regarding product specifications, delivery terms, payment schedules, and quality standards. These contracts serve as a binding framework to ensure resources and products are provided in a timely, efficient, and reliable manner. Key elements in these agreements often include:

- Payment Terms: Details on the payment method and timing.

- Discount Policies: Conditions for volume discounts based on order quantities.

- Return Policy: Terms for returning products in case of defects or other issues.

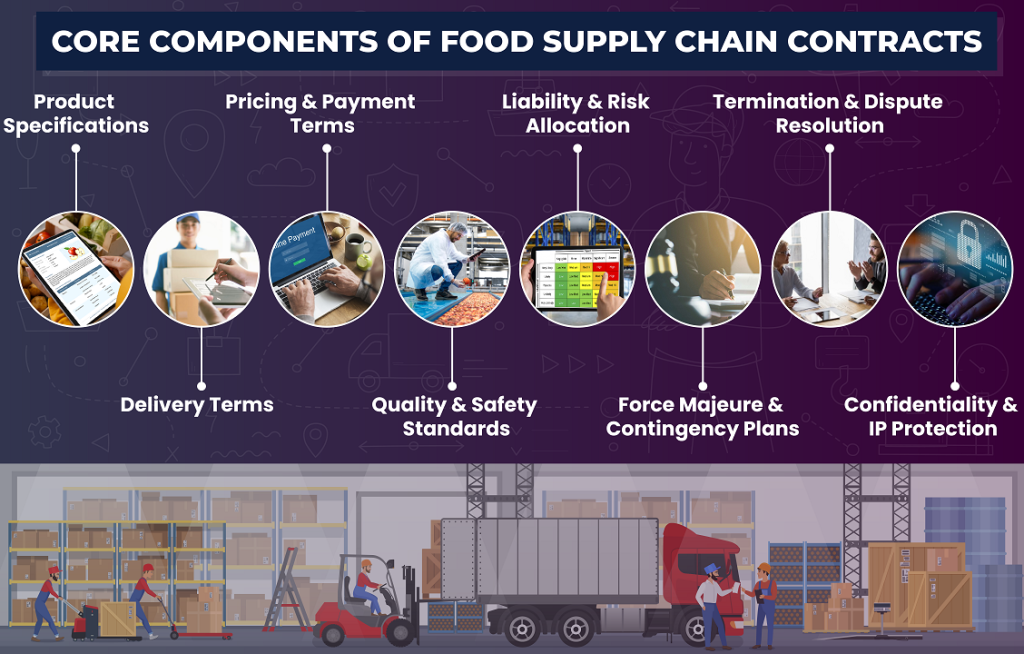

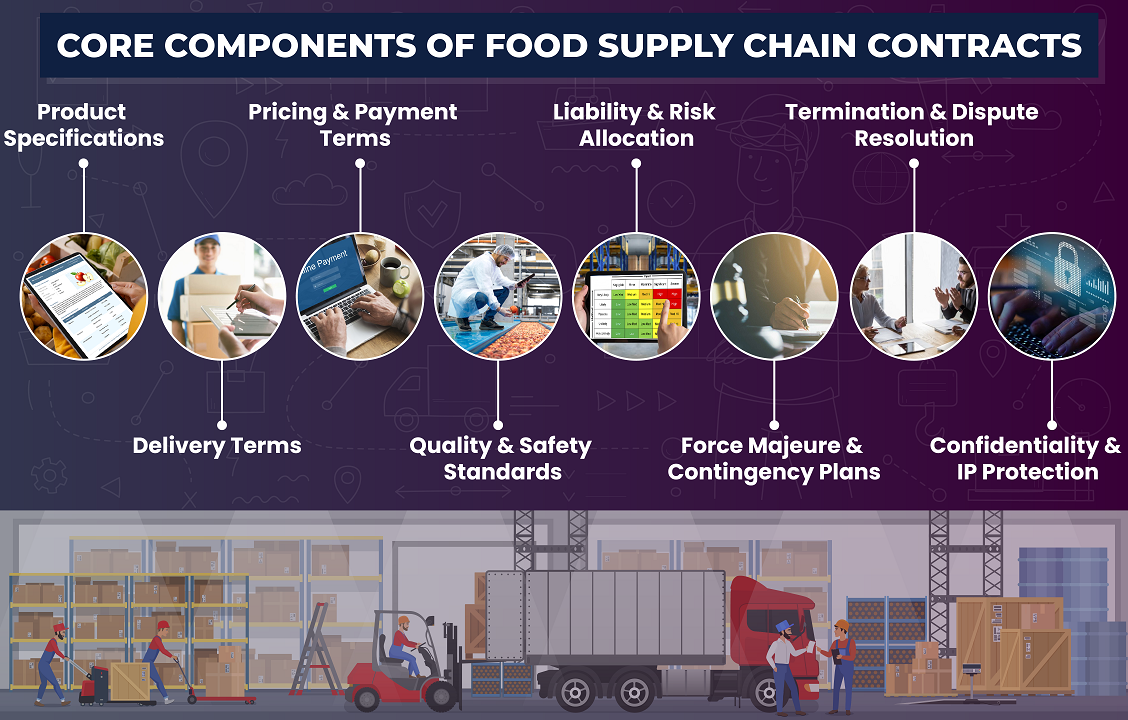

Core Components of Food Supply Chain Contracts

When drafting or evaluating a supply chain contract, food business owners should ensure the following elements are included:

⇒ Product Specifications

This section outlines detailed descriptions of the product, including quality standards, ingredients, labeling requirements, and more. Specifications should also account for potential changes, like sourcing adjustments, to maintain supply without sacrificing quality.

⇒ Delivery Terms

Clear delivery timelines prevent delays that can impact production schedules. Agreements should include a timeline for each phase of the supply process, including order placement, processing, and delivery. Penalties for late deliveries may also be incorporated.

⇒ Pricing & Payment Terms

Transparent pricing structures are vital. Outline costs for different product batches, potential volume discounts, and currency terms. Payment schedules and methods, such as bank transfers or credit terms, should be clearly specified to prevent disputes.

⇒ Quality & Safety Standards

This component details the necessary standards, including compliance with regulations like the Good Manufacturing Practices (GMP). Inspection procedures, quality checks, and any third-party certifications should be noted, along with the consequences for non-compliance.

⇒ Liability & Risk Allocation

Assigning responsibility for losses due to quality failures, delays, or regulatory non-compliance protects all parties. Liability clauses should define scenarios where a party may be liable, such as contamination incidents, and determine whether compensation or other actions are required.

⇒ Force Majeure & Contingency Plans

Including a force majeure clause safeguards your business during unexpected events (e.g., natural disasters, political upheavals). It’s wise to outline contingency plans and supplier alternatives for added security during supply disruptions.

⇒ Termination & Dispute Resolution

An exit strategy is crucial in cases where the business relationship can’t continue due to ongoing quality issues, financial concerns, or non-compliance. Specify terms for termination and dispute resolution methods like mediation, arbitration, or legal action if necessary.

⇒ Confidentiality & Intellectual Property (IP) Protection

Often, businesses share sensitive information with suppliers. Confidentiality agreements protect proprietary formulas, recipes, and data, ensuring that suppliers don’t share or replicate your business’s unique selling points or trade secrets.

Supply chain contracts are essential for business activities between two parties as they protect both sides by clarifying responsibilities, timelines, and quality expectations. However, many companies face challenges due to poorly crafted contracts, which can lead to disruptions or quality issues. Ultimately, well-structured supply chain contracts streamline the flow of goods, funds, and information from suppliers to end consumers while ensuring product quality meets the agreed standards.

Why Are Supply Chain Contracts Important in the Food Industry?

In every food business value chain, maintaining product quality and protecting a brand’s reputation is critical for businesses to thrive. This is especially true in the food industry, where supply chain contracts are imperative in ascertaining consistent quality and compliance.

Supply chain contracts can be mainstreamed in this aspect because they establish clear terms and expectations between parties involved in the production, distribution, and delivery of food products. This brings forth steady compliance with food safety standards, quality specifications, and regulatory requirements, helping to mitigate risks such as contamination, supply disruptions, and liability issues.

These contracts also enhance transparency and traceability, which are necessary for addressing recalls or incidents and maintaining consumer trust. They also outline pricing, delivery schedules, and dispute resolution mechanisms, fostering top-notch operations and stronger partnerships across the supply chain.

As consumer demand for premium products rises, so does the risk of quality degradation. If the quality of food declines, the brand’s reputation can suffer significant damage. To prevent this, companies implement well-defined supply chain contracts, ensuring that producers deliver goods that meet agreed-upon standards.

How Are Food Supply Chain Contracts Drafted & Negotiated?

Creating a solid supply chain contract involves comprehending the unique needs of your business and ensuring all terms are thoroughly discussed. Here are the best practices to consider:

-

Engage Legal & Industry Experts

Collaborate with legal experts specializing in food industry contracts. They will provide insights into compliance requirements and risks. Industry experts can also help identify best practices specific to your product or market.

-

Focus on Clear & Measurable Standards

Quality and safety standards should be specific, with measurable terms that can be tested. For example, if a supplier must adhere to a particular temperature during transport, this requirement should be measurable with data loggers.

-

Prioritize Transparency in Pricing & Terms

Pricing transparency not only prevents misunderstandings but also builds trust. Specify terms for price adjustments due to market conditions, currency fluctuations, or other factors that could impact cost.

-

Emphasize Flexibility for Growth & Adaptation

Long-term contracts should account for potential growth or market changes. Flexibility clauses allow you to adjust order volumes, and specifications, or even add new products to the contract as your business evolves.

-

Regular Review & Audit of Contracts

Regularly reviewing contracts ensures compliance with evolving industry regulations and quality standards. Audits also enable you to identify any areas needing updates or renegotiation based on supplier performance or changes in the business relationship.

Changing Scenario of Food Supply Chain Contracts

In the modern food supply chain, drafting and negotiating contracts have evolved significantly to address increasing complexities in business operations. Here’s a brief overview of what it comprises of:

- E-contracting: Digital platforms are increasingly used for contract drafting and negotiation, allowing real-time collaboration between suppliers, manufacturers, and retailers. Such platforms welcome seamless tracking of changes and legal binding of agreements through e-signatures.

- Supplier Audits & Certifications: Contracts often mandate that suppliers maintain certifications (e.g., ISO 22000, BRCGS) and undergo periodic audits to welcome ongoing compliance with safety standards.

- Sustainability Clauses: As ESG (Environmental, Social, and Governance) criteria become central, many contracts now incorporate sustainability commitments regarding ethical sourcing, reduction of carbon footprints, and waste management in food production and distribution.

- KPIs for Sustainability: Contracts may define specific Key Performance Indicators (KPIs) that suppliers must meet, such as reduced use of plastics or adherence to fair trade practices, with penalties or incentives tied to performance.

- Contingency Supply Plans: Contracts may specify alternative suppliers or contingency supply plans to maintain operations in case of a failure or breakdown in the primary supply chain.

- Food Traceability Systems: To reinforce supply chain transparency, contracts often include requirements for data sharing and traceability mechanisms to track food from farm to table.

- Data Ownership & Privacy: Negotiations frequently cover data ownership, usage rights, and privacy concerns, especially with the increasing use of digital tools and technologies that gather sensitive data on suppliers and products.

- Performance Metrics & Penalties: Contracts now include specific performance metrics that trigger the execution of follow-up actions, such as fines for late deliveries, quality failures, or unmet service-level agreements.

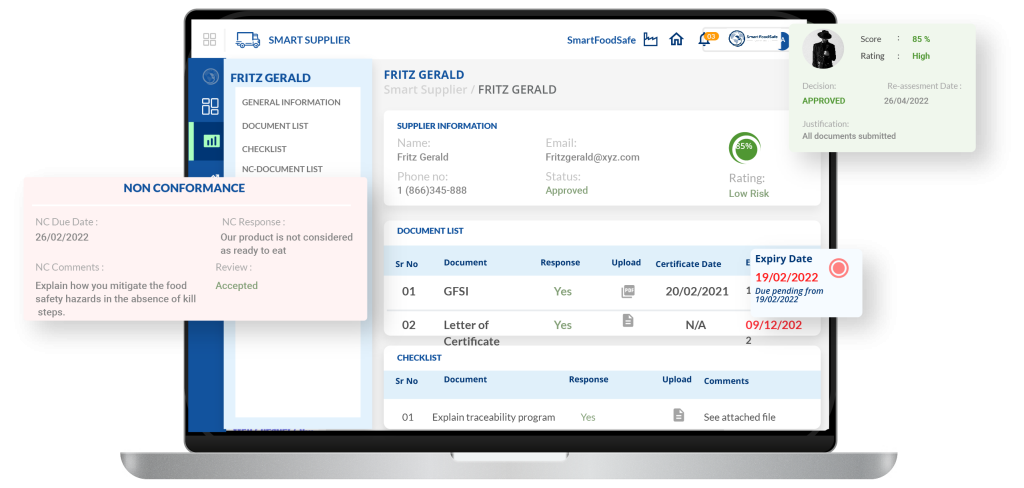

Smart Supplier is one of the pioneering solutions for food businesses to digitally take control of their supplier operations, within which supply chain contract management is a prominent part.

Smart Supplier for Smarter Supply Chain Contracts to Empower Food Businesses

Smart Supplier simplifies contract management by integrating supplier data and agreements into a centralized digital system. This eliminates manual paperwork, minimizes errors, and provides real-time visibility into contract statuses and performance metrics. Food businesses can define custom evaluation criteria, automate renewal alerts, and track key performance indicators (KPIs) to ensure supplier accountability. Whether you are dealing with multiple suppliers across regions or managing compliance with strict food safety standards, Smart Supplier offers the flexibility and intelligence to adapt to your unique business needs.